Support技术支持

3D Printing(SLA/SLS)

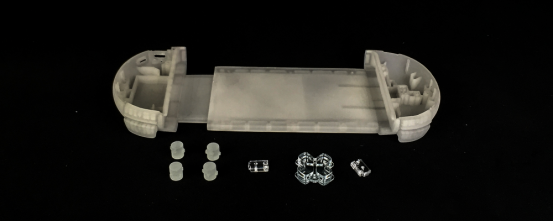

At Henry Prototype, we believe in an integrated approach to product development that is backed at every stage by exceptional engineering skill, cutting edge technology, and expert guidance. Our 3D printing service helps designers and engineers to develop and evaluate new products rapidly. A fast turnaround of your models is possible thanks to our extensive additive manufacturing capacity. Whether that’s a prototype to test form, fit and function, or as a starting point for any of our downstream manufacturing services, you will receive professional advice about the technology and material that best suits your needs.

3D printing is an additive manufacturing technology which is used to produce prototypes in either plastic or metal layer by layer directly from 3D CAD data under computer control. A few methods include the use of curing, melting or sintering the material in order to produce prototype parts. At Henry Prototype, we offer stereolithography, selective laser sintering, fused deposition modeling and direct metal laser sintering 3D printing services. 3D printing offers maximum design freedom and flexibility in materials in terms of mechanical and thermal properties. Our in house finishing team can accomplish a range of surface finish levels, with or without primer, color matched paints, polishing, and texturing.

Range of prototype materials

Henry Prototype provides a range of 3D printing materials to ensure prototypes are built in a material that fit your needs. At Henry Prototype, we keep a ear close to the ground for the latest developments in resins and our experts have selected a range to cover most applications. What’s more, we’re frequently asked by suppliers to beta test resins, allowing us to see some of the new materials that may be coming to the market.

Furthermore, our prototyping centers fulfill local demand and also work together as a team to share capacity, expertise, and material options to ensure we meet our customers’ requirements, timescales, and specialist needs. By working as a team we can collaborate on projects that in some cases may be more than one site could handle. Our experienced team will work closely with you to understand your product development requirements while maintaining focus on manufacturability, cost efficiency, and product release goals.

Precision:±0.05

Available Materials:ABS,PMMA,PA, Somos 14120, others on request.

Max size :600×600×400mm

- Home

- |

- About us

- |

- Product

- |

- News

- |

- Contact us

Email: info@henryproto.com

freequote@henryproto.com

Copyright:Hongkong Henry Prototype Co.,Ltd

Design by heyou51.com

China

China English

English